Our partner is among the best with over 45 years of experience. Most cutting-edge facilities with a sizable staff of highly skilled, knowledgeable, and trained personnel to handle all of your maintenance requirements.

For more information about our maintenance capabilities and how we can help you save money and time by repairing your current equipment line, call us or send us an email.

OUR PARTNER EQUIPMENT MAINTENANCE CAPABILITIES

- Repair and Re-wind Low and High Voltage Motors/ Alternators.

- Repair and Overhauling of all types and make of rotating equipment (Centrifugal / Positive Displacement Pumps, Centrifugal / Reciprocating Compressors, Vacuum Pumps, Steam Turbines, Gearbox)

- Repair and Overhaul Siemens Light Industrial Gas Turbines.

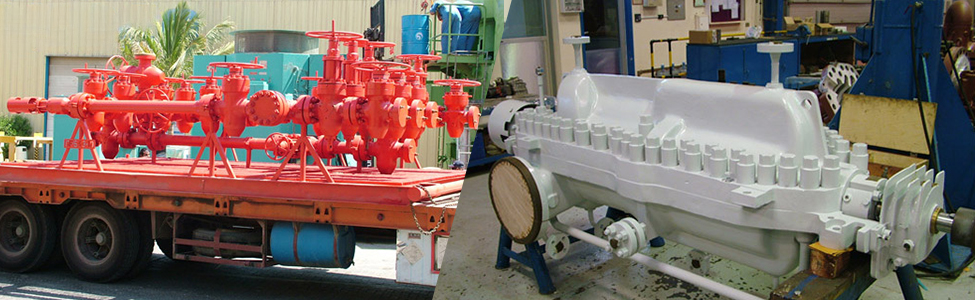

- Repair and Re-manufacture Blow out Preventers. (Authorized Repair Facility for Hydril)

- Manufacture of oilfield accessories to A.P.I. specifications.

- Re-cut Oilfield Premium Connections. (Authorized Repair Facility for TenarisHydril and Voest Alpine).

- Carry out the complete Operation and Maintenance of Waste Water Treatment Plants and Asset management of various industries.

OUR PARTNER FACILITY CERTIFICATION & LICENSES

- API SPEC 5CT Casing & Tubing (LICENSE # 0430)

- API SPEC 6A Wellhead and Christmas tree equipment (LICENSE # 0661)

- API SPEC 7-1 Rotary drill stem elements (LICENSE # 0610)

- API SPEC 16A Drill through equipment (LICENSE # 0157)

- API SPEC 16C Choke and Kill systems (LICENSE # 0457)

IMS CERTIFICATION

Quality IMS Certification for ISO 9001:2015, ISO 14001:2015, ISO45001:2018

OUR PARTNER FACILITY AND EMPLOYEE CERTIFICATIONS

- ASNT Level III personnel- RT

- ASNT Level II NDE Inspectors into methods of MT, PT, VT, RT, UT.

- Welding inspector – CSWIP Qualified

- Painting inspector – NACE CIP -Level-II (SSPC) Qualified

- Qualified Lead Auditor / Internal Auditor – API Q1 / ISO 9K, 14K & 45K.

- Inhouse calibration facility for linear measuring instruments & pressure gauges.

- NEBOSH & IOSH qualified safety personals

- OEM certified Quality Inspector to inspect premium connection.

- The testing capability includes the following:

- NDE equipment of Yoke, Coil, Semiconductor, and UT thickness gauge.

- Hardness testing- King, Equotip, Shearpin

- Positive Material Identification – Spectro & XRF

- Borescopic Inspection

- Hexagon Romer Arm / 3D Scanner

- Coating and painting test equipment (Holiday test, Shear Strength, and Adhesion test)

- Thread gauges, (API, STUB ACME, NPT, UNC, and UN type)